Heavy industries with stringent demands on airflow and mechanical performance put their trust in very reliable components to ensure the continued operation. Among those, Carbon Vanes in Mumbai, like Dmaic Carbon Private Limited, have become popular for a huge number of applications. These are the vanes that govern optimum pressure and flow control within devices as vacuum pumps, compressors, and air motors. Function and form maintenance under heavy friction and high-speed environments are what garners their precedence in industry subfields such as automotive, packaging, and HVAC.

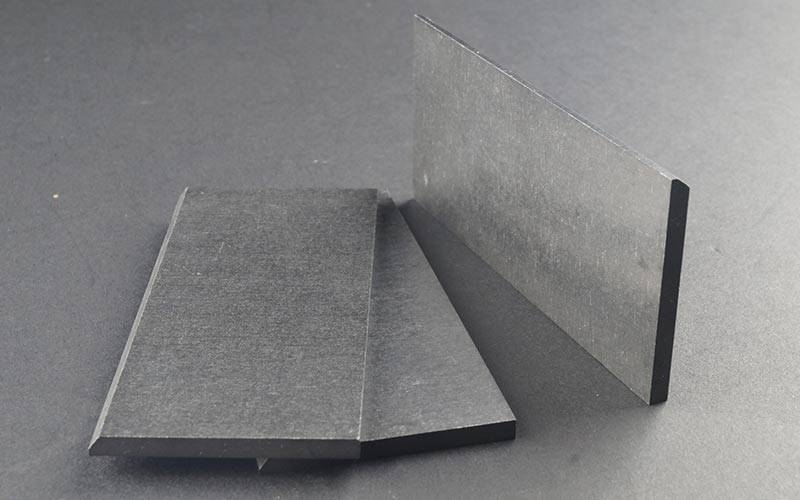

Thanks to their durability, these vanes can be one of the most significant advantages. They are manufactured from the most modern materials of carbon graphite and boast a very high degree of resistance to wear, even when being operated continuously. This makes them last long in the performance of their functions without frequent replacement or wear. Their chemical inertness protects them from high temperature conditions and, likewise, dry-running situations from corrosion over time. This reliability ensures less downtime and, in turn, increases the lifespan of the entire equipment.

Another salient advantage is unmatched efficiency. These vanes are designed to flatten and maintain constant contact between the housing surfaces, thereby creating a stable compression and vacuum pressure, adapting excellently to fluctuating speeds and pressures, making them ideal for high-performance machinery. Being light and much self-lubricating achieves maximum effectiveness without an additional lubrication system, thus minimizing energy consumption and maximizing smooth functioning in the field of industrial units.

Adaptability of carbon vanes is the reason for their widespread use. They fit everywhere: from pharmaceuticals to food processing to printing; they fit into many different types of machines and around many different environments. They withstand aggressive chemicals and changing temperatures without loss of structural integrity. It gives such broad compatibility that companies can standardize performance across the fewest applications with the least number of different parts.

One thing that a seatmaker knows precisely is that it takes a lot of precision, material selection, and manufacturing activity to make the veneers perform well. Carbon Vanes Manufacturers in Mumbai invest too heavily in research and development to tag in a form of vane for high vacuum, or low noise, or dry operation; those custom-designed components meet global standards, yet address the nuances of niche applications, allowing some engineers ample room for exploration. By having advanced machining, manufacturers prefer not to deviate from stringent tolerances that offer consistent performance for each vane.

Stay updated with the latest insights and innovations in carbon technology and advanced materials. Our blogs explore industry trends, product applications, and expert tips to help you make informed decisions. Dive into topics that highlight durability, efficiency, and cutting-edge solutions designed to optimize performance across various sectors. Discover knowledge that empowers your next project.